Asbestos, once a popular building material, poses serious health risks when disturbed, especially in roofing and other construction materials often found in the UK.

Understanding its dangers, identifying its presence, and knowing how to remove it safely is crucial for homeowners, contractors, and building professionals alike.

This article guides you through the essentials of asbestos, highlights where it may be lurking in your roof or garage, and provides a step-by-step approach for safe removal and encapsulation.

You will also discover proper disposal methods and alternatives to removal, such as encapsulation, ensuring a comprehensive understanding of how to manage this hazardous material and comply with legal requirements.

Stay informed and protect your space from the risks associated with asbestos exposure by having a solid asbestos management plan in place.

Contents

Asbestos is a naturally occurring fibrous mineral that is widely used in the construction industry, particularly in the UK, due to its heat resistance and strength. It was commonly found in materials such as asbestos cement sheets and roofing materials, especially in buildings constructed during the 1960s and 1970s.

However, its use has been heavily regulated and largely banned due to the serious health risks associated with exposure to asbestos fibres, which can lead to asbestos-related diseases, including mesothelioma and asbestos-related lung cancer.

Dig Deeper: What Is Asbestos

Asbestos is dangerous primarily due to the health risks it poses when its fibres are released into the air, leading to inhalation and potential long-term health consequences. Exposure to these hazardous materials can result in severe asbestos-related diseases such as mesothelioma, asbestosis, and asbestos-related lung cancer, which have been linked to increased risk among workers in the construction industry, public buildings, and residential properties.

The Health and Safety Executive (HSE) outlines strict legal compliance measures to manage asbestos safely and protect public health.

Asbestos can often be found in various roofing materials, particularly in older buildings, with asbestos roofs being a significant concern for homeowners and property managers.

Commonly used in the construction of roofs and other building materials, asbestos cement was popular due to its durability and resistance to fire. Properties with an asbestos roof should undergo regular inspections to check for any signs of deterioration or damage.

In residential properties constructed before the 1980s, roof panels and coverings may contain hidden asbestos fibres, necessitating a thorough inspection by a qualified asbestos surveyor and survey to identify hazardous materials.

Identifying the signs of asbestos in a roof is crucial for ensuring home safety and compliance with legal requirements, particularly in properties built with materials like asbestos cement sheets. Warning signs should trigger immediate actions such as hiring asbestos removal professionals for a thorough inspection and possible removal.

Warning signs can include visible deterioration of roofing materials, such as crumbling, cracking, or frayed edges, which may release hazardous fibres into the air. Regular inspections and building surveys are essential for detecting these signs, especially in older buildings where asbestos roofing is commonly used.

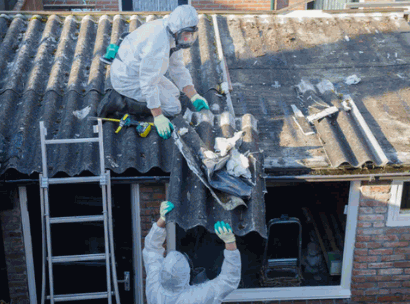

Safely removing asbestos sheets from a roof is a complex and hazardous process that should only be carried out by trained asbestos removal professionals to ensure safety and legal compliance. Engaging a licensed team can also help manage removal costs effectively and ensure all legal obligations are met.

The removal process involves several critical steps, including assessment of the site, preparation of the area, and employing the correct protective equipment to prevent exposure to toxic fibres.

Homeowners must prioritise safety and engage a licensed team experienced in handling asbestos materials to manage the risks effectively.

Engaging a professional asbestos removal service is vital for ensuring the safe handling and disposal of hazardous materials, as well as complying with legal requirements in the UK. Trained asbestos teams possess the knowledge and experience to execute the removal process safely, minimising the risks of exposure to harmful fibres during the operation. It is also essential to have an asbestos management plan in place for continuous monitoring and maintenance.

Utilising certified experts not only guarantees the implementation of best practices but also protects homeowners, employees, and the environment from the dangers posed by asbestos. These specialists are equipped with advanced tools and protective gear, thereby significantly lowering the odds of any contamination during the project. They are well-versed in the legal obligations associated with asbestos removal, ensuring that all local regulations and guidelines are meticulously followed.

To find reputable services, consider checking reviews, asking for recommendations, and confirming that the contractors have proper certifications and insurance. This due diligence will not only help you find a reliable team but also give you peace of mind, knowing the removal is in safe hands. It is also important to obtain a clearance certificate after the completion of the removal process to ensure no asbestos fibres remain.

Preparing the area for asbestos removal is a critical step that involves clearing the work site and ensuring that safety measures are in place to protect workers and bystanders alike. An asbestos management plan outlining the process, responsibilities, and safety protocols is essential in this preparatory stage.

This essential preparation includes sealing off the area with proper containment barriers to prevent any airborne particles from spreading. Air monitoring throughout the process can further ensure that asbestos fibres do not escape the contained area.

It’s important to inform all occupants about the ongoing work, providing them with clear guidelines and timelines to ensure their safety and peace of mind.

Utilising appropriate Personal Protective Equipment (PPE) such as respirators, gloves, and disposable coveralls is imperative for all personnel involved in the project. Proper training on the use of this equipment should be provided to all team members to ensure maximum safety.

Implementing effective dust control measures, such as wetting the materials before removal or using specialised vacuum systems, can significantly reduce the risk of asbestos exposure. These measures are essential parts of the encapsulation process that help in handling asbestos safely.

Conducting thorough training for workers on safety protocols will enhance readiness and compliance during the removal process.

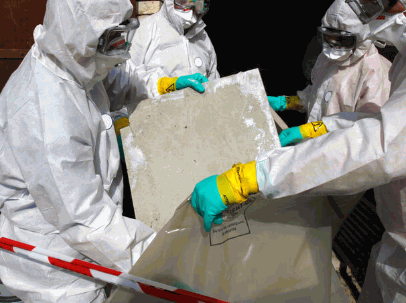

Wearing appropriate protective gear is essential when handling asbestos to prevent any exposure to harmful fibres, ensuring the safety of all individuals involved in the removal process. This gear typically includes disposable coveralls, gloves, respirators fitted with HEPA filters, and eye protection to provide a comprehensive barrier against asbestos dust.

Ensuring that all team members adhere to safety protocols is vital in maintaining a secure working environment. The effectiveness of this protective equipment diminishes significantly if not worn correctly; therefore, it is crucial to educate workers on proper usage.

The following types of protective equipment should always be present during asbestos handling:

By utilising this equipment responsibly, the risk of exposure is significantly mitigated, ensuring a safer and healthier workspace for everyone involved. Regular maintenance and inspection of protective equipment are also necessary to ensure their effectiveness during the asbestos removal process.

Before removing asbestos sheets, it is crucial to wet them thoroughly to minimise the release of hazardous fibres into the air, thereby enhancing safety during the removal process. Wetting the asbestos helps to keep the fibres contained and reduces the risk of inhalation during the handling of these materials. Proper waste disposal methods must be followed to safely manage asbestos waste generated during the process.

The process of wetting is not merely a precaution; it is an essential practice that significantly lowers the chances of airborne contamination. A fine mist of water is typically applied using a garden sprayer or similar equipment, ensuring even distribution to saturate the sheets without causing runoff. This method serves several purposes:

It is advisable to establish a containment area to prevent the spread of any loose fibres, ensuring that the site remains secure while asbestos is being handled.

Carefully removing asbestos sheets is a critical part of the process that requires precision and caution to avoid disturbing the material and releasing fibres into the environment. An asbestos expert should supervise this stage to ensure all procedures follow legal compliance and best practices.

This crucial stage not only safeguards the health of workers but also protects the surrounding community from potential exposure. Professional removal teams utilise a variety of specialised equipment such as HEPA-filtered vacuums and protective clothing to minimise risks.

Adherence to proper asbestos management and:

is essential. By employing methods that limit movement and vibration during the removal process, they ensure that asbestos fibres remain contained. Utilising tools like pneumatic wrenches and cutting blades designed for such materials facilitates the careful detachment of these sheets.

Constant monitoring of air quality is performed to identify any potential fibre release during removal, reinforcing the vital nature of safety protocols, as outlined by the Health and Safety Executive (HSE).

Proper management of asbestos waste is crucial to maintaining safety and complying with legal regulations following the removal of asbestos materials (ACMs) from a property.

Asbestos waste must be handled and disposed of by licensed professionals who follow strict guidelines to prevent environmental contamination and health risks associated with hazardous waste materials.

Disposing of asbestos safely involves adhering to stringent legal requirements and guidelines designed to protect public health and the environment from hazardous materials. This process typically requires the involvement of licensed disposal professionals, who can ensure that asbestos waste is transported and disposed of in a manner that complies with UK regulations.

For property owners facing asbestos concerns, understanding the alternatives to removal is essential for effective asbestos management while ensuring safety. Two commonly recommended alternatives are encapsulation, which involves sealing asbestos materials to prevent fibre release, and enclosure, which entails constructing a barrier around the asbestos to minimise exposure, thus providing a viable solution for managing asbestos without removal.

Encapsulation is a method used in asbestos management that involves applying protective layers over asbestos-containing materials to prevent the release of harmful fibres into the air.

This approach can offer a safer alternative to removal, particularly when the asbestos is in good condition and poses minimal risk.

Understanding the encapsulation process requires a closer look at the materials employed, which typically include specialised sealants and coatings designed to securely bond to the asbestos surface.

Techniques of application vary, ranging from spray-on methods to brush or roller applications, ensuring complete coverage.

Adherence to safety guidelines is crucial; workers must don appropriate personal protective equipment (PPE), including respirators and protective suits, to mitigate exposure during the process. As per UK regulations, proper safety measures must always be in place.

Special attention should also be given to the proper disposal of any equipment that comes into contact with asbestos, further guaranteeing that any potential hazards are minimised.

Enclosure involves constructing a physical barrier around asbestos materials to contain them and prevent exposure to hazardous fibres, serving as another effective method in asbestos management. This technique is particularly useful in scenarios where removal is not feasible or would cause more harm than good.

The enclosure process typically utilises a combination of durable materials such as plywood, metal sheets, and specialised containment fabrics. These elements are often chosen for their strength and ability to withstand environmental factors, thereby ensuring a long-lasting solution. Proper installation methods include:

Safety considerations during the enclosure process are paramount. It is crucial to ensure that the work area is adequately ventilated, and personal protective equipment (PPE) is used by all personnel involved. Adhering to local regulations and industry best practices, such as those recommended by the Health and Safety Executive (HSE), is essential to minimise any risk associated with asbestos exposure.

Professional repair of asbestos-containing materials is an alternative approach that involves sealing or repairing damaged asbestos rather than complete removal, which helps to manage safety risks effectively. This method is typically carried out by licensed professionals who are trained to handle asbestos safely and ensure that the integrity of the materials is maintained.

Such an approach not only minimises disruption within occupied spaces but also significantly reduces the potential for exposure during the remediation process. Professional repair offers several advantages:

There are specific scenarios where repairing is more beneficial than removal, such as:

Regardless of the method chosen, adhering to strict safety measures is crucial. This includes utilising appropriate personal protective equipment (PPE), implementing proper containment procedures, and conducting thorough air quality assessments post-repair to ensure a safe environment.

Preventing asbestos exposure is crucial for safeguarding health, particularly in buildings that may contain asbestos materials.

Effective measures include implementing a regular inspection and maintenance plan to identify and manage potential asbestos hazards, thereby reducing the risk of fibre release and enhancing overall safety in properties where asbestos is present. This includes periodic checks for the condition of ACMs and ensuring any issues are promptly addressed.

Implementing a regular inspection and maintenance plan is vital in preventing asbestos exposure, as it allows property owners to monitor the condition of asbestos materials and address any issues promptly. Regular assessments help identify deterioration and potential risks, ensuring that appropriate safety measures are upheld.

Incorporating a systematic approach to routine inspections not only minimises health hazards but also enhances overall property management. Implementing a maintenance plan for regular inspections is vital. During inspections, property owners should focus on several key areas:

By documenting these findings, owners can develop a comprehensive management plan that prioritises safety and compliance with regulations. Regular training for maintenance staff is also crucial, ensuring that they recognise potential hazards and report any concerns swiftly.

Educating yourself and others about asbestos is a crucial step in preventing exposure and ensuring safety, as awareness promotes understanding of the risks and proper handling procedures.

Knowledge about the dangers associated with asbestos can give the power to communities to take action, fostering a culture of safety and vigilance. Understanding how asbestos fibres can enter the air and be inhaled is essential for minimising exposure, especially in older buildings where this hazardous material was commonly used. As such, implementing community educational programmes is vital for disseminating important information about asbestos and its risks.

Numerous resources are available for those seeking to learn more about handling asbestos safely. Government websites, health organisations, and non-profit groups all provide fact sheets and guidance on safe practices. By utilising these resources effectively, individuals can gain the knowledge they need to protect not only themselves but also their communities from the risks associated with asbestos.

Following established safety guidelines when working with asbestos is essential for minimising risks and ensuring effective management of hazardous materials. This includes using protective equipment, employing safe handling techniques, and adhering to legal compliance measures to safeguard health during any maintenance or removal work.

When tackling tasks that involve asbestos handling, individuals must prioritise their safety by strictly following specific protocols. These protocols entail:

Engaging with certified professionals who understand the complex regulatory landscape in the UK is crucial. Such experts not only ensure the effective removal of Asbestos but also guarantee compliance with all local and national regulations, including those set by the Health and Safety Executive (HSE).

By understanding the significance of these safety measures, individuals contribute to a safer environment for themselves and others.